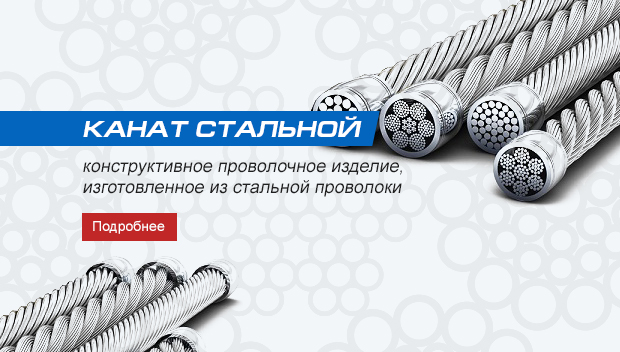

The basic characteristics of ropes

Steel ropes - the basic elements of the majority of load-lifting, transport, road-building, digging machines and mechanisms - are one of the most widespread kinds of hardware and find wide application in various industries of the national economy: coal, mining, oil refining; transport and agricultural mechanical engineering, the building industry; marine and river vessels, etc.

Steel ropes are a complex and important kind of wire products. They are manufactured in various types and constructions, and differ in the form of rope and its elements cross section, as well as in physical and mechanical characteristics of wires and cores.

The correct choice of type, design and properties of rope elements, based on the rope purpose and application condition, in many respects determines both rope durability and normal work of load-lifting machines and mechanisms. Our products are precisely manufactured to ensure optimum strength, safety, service and economy.

The ropes manufactured are classified to the following characteristics:

- Form of the rope cross section: round.

- Form of the rope elements cross section: round-stranded, trihedral-stranded, closed design.

- Wire mechanical properties:

general purpose ropes: mark “ВК” - high quality, mark “В” - increased quality, mark “1” - normal quality;

other ropes: mark “В” - high quality, mark “1” - normal quality. - Tensile strength: 1370 (140), 1470 (150), 1570 (160), 1670 (170), 1770 (180), 1860 (190), 1960 (200), 2060 (210), 2160 (220).

Ropes with tensile strength 1370 (140) - 1770 (180) have serial production, the rest are manufactured by inquiry. - Wire surface coating: without coating; with zinc coating - for especially rigid aggressive operating conditions (ERA), for rigid aggressive operating conditions (RA), for average aggressive operating conditions (A).

- Application purpose of a rope:

- lifting and transporting people and cargoes;

- cargo transportation.

|

|

|

Rope Section:

а – a round-stranded rope; b - a closed design rope; c – a trihedral-stranded rope

- Core material:

- fiber core (FC) from natural or synthetic materials;

- steel core (IWRC - Independent Wire Rope Core).

- Lay direction of rope elements: right lay; left lay.

- Combination of rope and its elements lay direction:

- cross lay: direction of rope strands lay is opposite to direction of strand wires;

- long lay: rope strands direction and strand wires is identical.

- Twisting degree:

-

twisting ropes with identical lay direction of all strands in every layer of a rope (6 and 8-strand ropes with organic and metal cores);

-

ropes with little twisting degree having an opposite lay direction of rope elements on layers (in multi-lay ropes, multi-strand and single-lay ropes).

-

а |

|

|

|

Direction and combination of rope lays:

а - left cross lay; b - right cross lay; c - left long lay; d - right long lay

-

Way of manufacturing: untwisting (H) - elements of a rope keep the position after fastening removal from the rope ends; untwisting; straightened (P).

-

Lay type of strands and long lay ropes: with dot wire contact between layers (TK); with linear wire contact between layers (ЛК); with combined dot-linear contact of wires between layers (ТЛК).

-

Manufacturing accuracy: normal accuracy; increased accuracy (A), with tightened extreme deviation from the rope diameter. The basic technical requirements to ropes, test methods, requirements on physico-mechanical and construction characteristics of steel ropes are stipulated in GOST 3241-80 "Steel ropes. Specifications ".